Crystal Clear Durability: Polycarbonate Roofing for Car Wash Sites

Car wash facilities present a unique and demanding environment for building materials. Constant exposure to water, chemicals, and fluctuating temperatures can quickly degrade conventional roofing. This is where polycarbonate roofing sheets shine, offering an ideal solution for car wash sites that prioritizes durability, natural lighting, and resistance to harsh conditions.

The Unique Roofing Challenges of a Car Wash

A car wash isn't just a wet environment; it's a dynamic industrial setting with specific stressors:

- Constant Water Exposure: High-pressure water, steam, and continuous moisture ingress.

- Chemical Splash: Detergents, waxes, and cleaning agents that can corrode certain materials.

- Humidity and Condensation: Leading to mold, mildew, and material degradation.

- Temperature Extremes: Often operating in both hot summers and cold winters.

- Brightness and Visibility: Essential for both customer perception of cleanliness and operational safety.

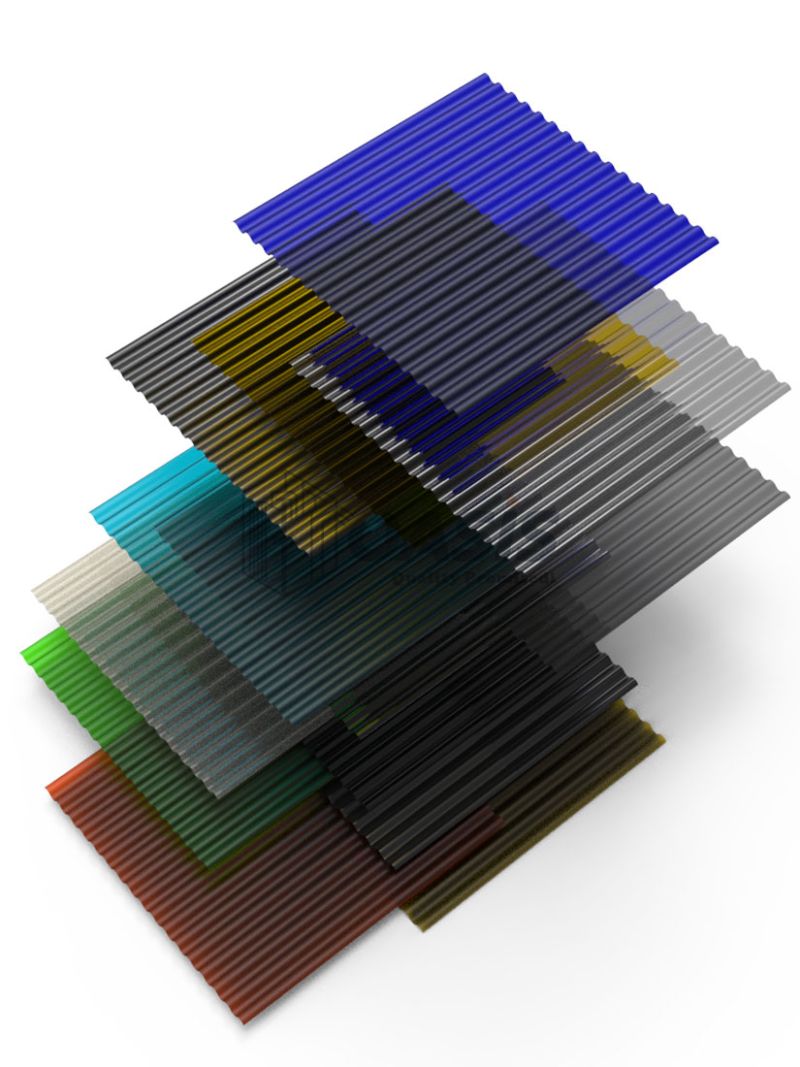

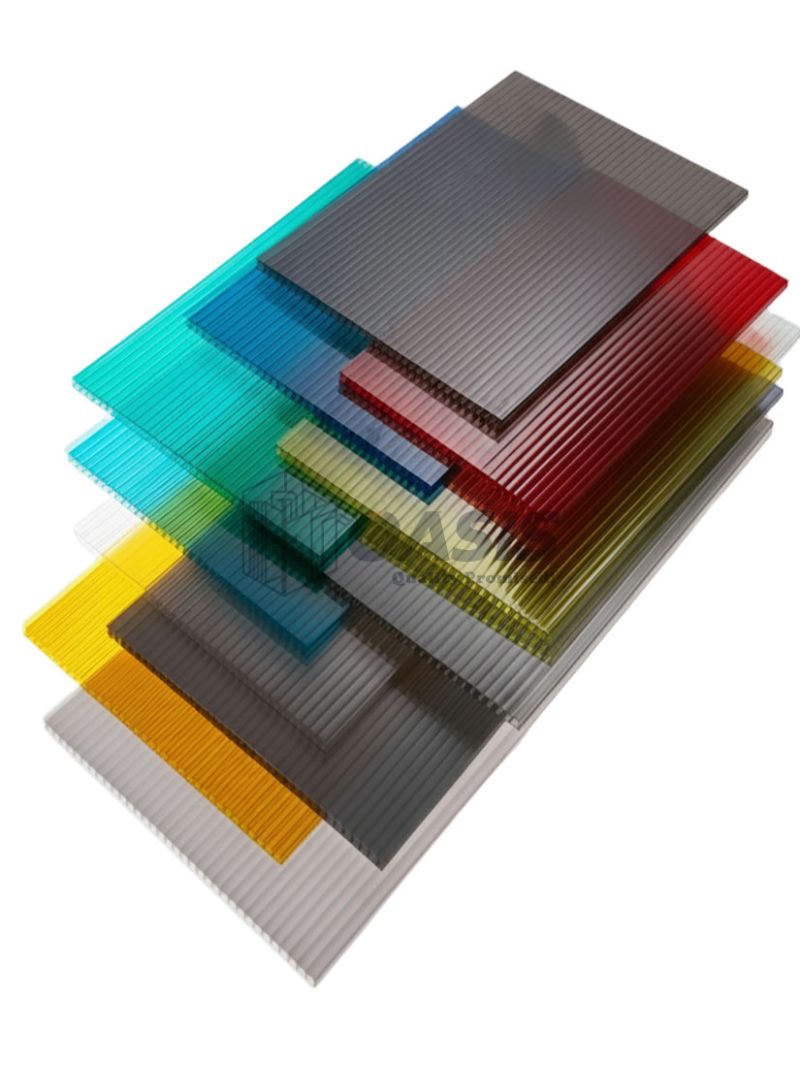

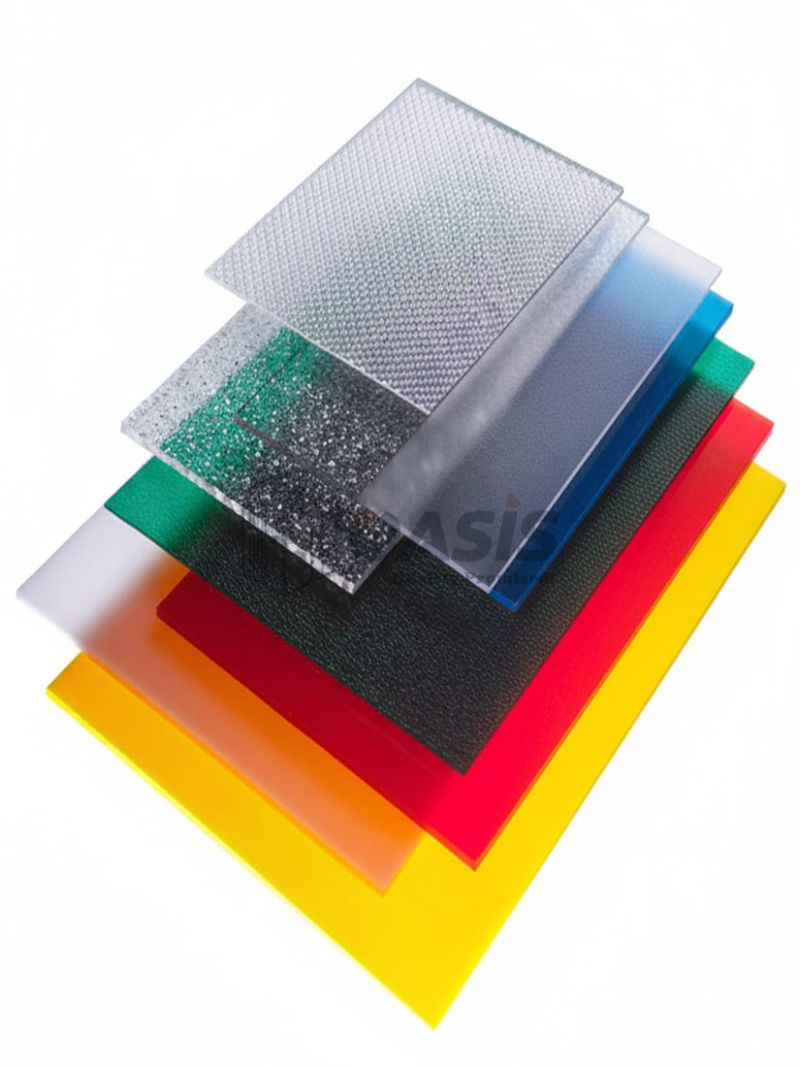

Why Polycarbonate is the Superior Choice for Car Wash Roofing

Polycarbonate roofing sheets are engineered to not just survive but thrive in such conditions, offering specific advantages over traditional roofing options:

1. Unmatched Transparency and Natural Lighting

This is a critical advantage for car wash businesses.

- Bright, Inviting Space: Clear or translucent polycarbonate allows a high percentage of natural daylight to flood the wash bays. This creates a bright, airy, and more inviting atmosphere for customers, enhancing the perception of cleanliness and modernity.

- Reduced Energy Costs: Maximizing natural light significantly cuts down the need for artificial lighting during the day, leading to substantial energy savings for the facility.

- Improved Visibility and Safety: Better natural illumination improves visibility for both customers (checking their car's cleanliness) and staff (operating equipment safely).

2. Extreme Durability and Impact Resistance

Polycarbonate is renowned for its strength, a vital feature in an industrial setting.

- Virtually Unbreakable: Polycarbonate is up to 200 times stronger than glass and highly resistant to impact. This protects against accidental knocks from equipment, high-pressure water jets, or even vandalism.

- Weather Resilience: It withstands hail, heavy snow loads, and strong winds without cracking, shattering, or degrading, ensuring long-term structural integrity.

- Corrosion-Proof: Unlike metal roofing, polycarbonate does not rust or corrode from constant water or chemical exposure, guaranteeing a longer lifespan in the car wash environment.

3. Chemical and Moisture Resistance

The very nature of polycarbonate makes it highly suitable for wet and chemically active sites.

- Resistant to Cleaning Agents: Polycarbonate is largely unaffected by the types of detergents, waxes, and cleaning chemicals used in car washes, maintaining its clarity and structural integrity over time.

- No Mold or Mildew: Its non-porous surface does not absorb moisture, preventing the growth of mold, mildew, and algae, contributing to a cleaner and more hygienic facility.

4. UV Protection

Crucial for protecting both the material itself and anything underneath.

- Integrated UV Layer: Polycarbonate sheets come with a co-extruded UV-protective layer that blocks harmful UV radiation. This prevents yellowing and brittleness of the sheet over time and protects interior components, paintwork on cars (if exposed), and even staff.

5. Thermal Performance

Managing heat is essential for comfort and operational efficiency.

- Temperature Stability: Polycarbonate performs well across a wide range of temperatures without becoming brittle in the cold or deforming in the heat.

- Heat Reduction Options: Tints (like opal or bronze) are available to help reduce solar heat gain, preventing the wash bay from becoming excessively hot in direct sunlight, thereby improving comfort for both customers and staff.

Ideal Applications at a Car Wash Site

- Wash Bays/Tunnels: The primary area where transparency and durability are most needed.

- Drying Bays: Allowing natural light while protecting from lingering moisture.

- Vacuuming and Detailing Canopies: Providing shelter for customers and their vehicles during detailing, keeping the area bright.

- Entrance and Exit Canopies: Creating a welcoming, sheltered pathway into and out of the wash.

In conclusion, polycarbonate roofing sheets offer a comprehensive solution for car wash sites. Their unparalleled combination of high light transmission, extreme durability, chemical resistance, and low maintenance creates a brighter, safer, more inviting, and ultimately more profitable car wash operation.