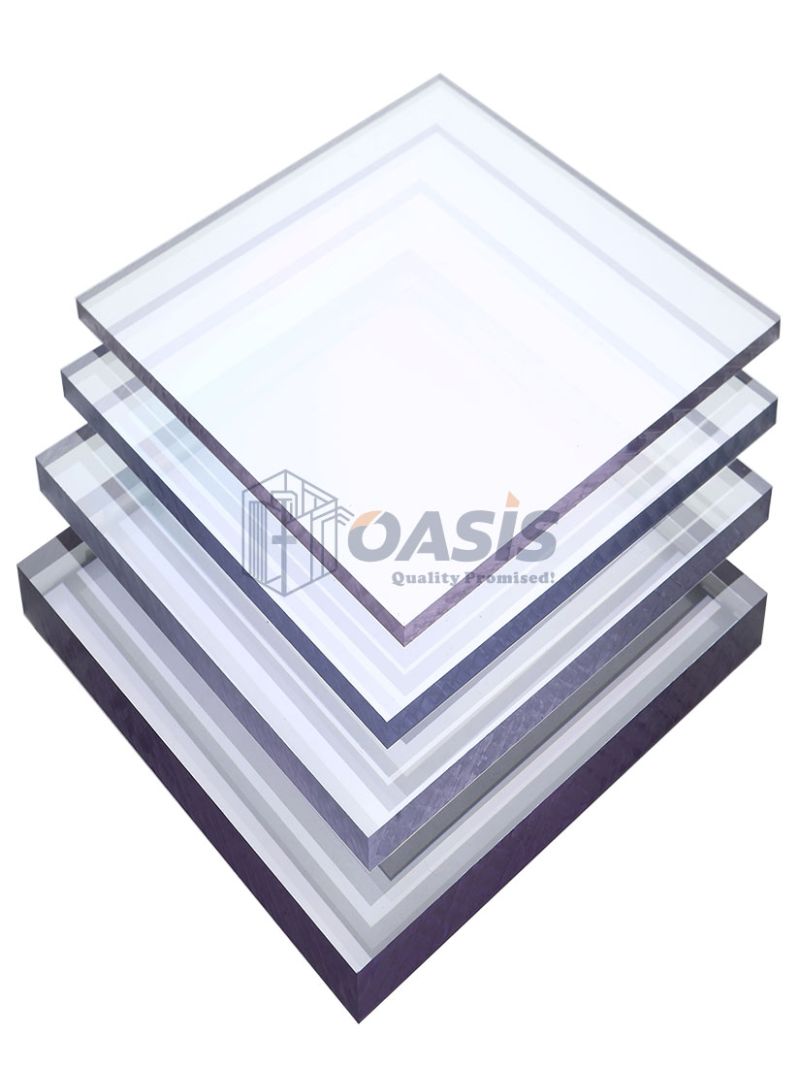

Illuminated Branding: Polystyrene Frosted Sheets for LED Light Boxes

Polystyrene frosted sheets have become a prevalent and cost-effective material in the signage and display industries, particularly as the face of LED light boxes. These sheets offer the critical balance of excellent light diffusion, durability, and cost-efficiency required to produce brightly, uniformly lit graphics for retail, advertising, and corporate branding.

The Importance of the Light Box Face

The success of any modern light box hinges on the material used for its face (the diffuser). This material must achieve two conflicting goals: it must be thin enough to transmit light efficiently yet opaque enough to fully conceal the LED light sources (the "hot spots") and distribute the light evenly across the graphic.

Polystyrene frosted sheets excel in this role, offering properties perfectly tailored for LED illumination:

1. Superior Light Diffusion (The "Frosted" Effect)

The frosted finish is the material’s defining feature for light box applications.

- Hides Hot Spots: The microscopic texture or additive within the sheet effectively scatters light in multiple directions. This diffusion eliminates visible "hot spots" (bright dots from individual LEDs), ensuring the entire sheet surface glows with a smooth, uniform brightness.

- High Transmission: Despite the frosting, the sheet allows a high percentage of visible light to pass through, ensuring the printed graphics remain vivid and eye-catching without requiring excessive power consumption.

- Color Consistency: It helps maintain the integrity and consistency of the colors printed on the light box graphic.

2. Cost-Effectiveness and Processing

Compared to alternatives like frosted acrylic or polycarbonate, polystyrene offers significant commercial advantages.

- Budget-Friendly: Polystyrene is generally one of the most economical plastics available, significantly reducing the material cost for large-scale sign manufacturing and multi-location rollouts.

- Ease of Fabrication: The material is easy to cut, rout, and drill using standard tools. This rapid fabrication process contributes to faster production and lower labor costs.

- Thermoforming: While light box faces are typically flat, the material can be thermoformed (heated and molded) into curved or shaped displays if required.

3. Lightweight Durability

For large sign applications, reducing weight is essential for installation and long-term safety.

- Reduced Structural Load: Polystyrene is very lightweight, simplifying the hanging and mounting of the light box structure, especially on interior walls or retail fixtures.

- Sufficient Durability: High-Impact Polystyrene (HIPS) is commonly used, providing a good balance of rigidity and impact resistance, ensuring the face can withstand handling during installation and minor retail environment bumps.

Key Applications in Signage

- Retail POP (Point-of-Purchase) Displays: Used in shelving units, counter displays, and window graphics to advertise products.

- Menu Boards: Backlit panels in fast-food restaurants and cafés for displaying menus and promotions.

- Exhibition Booth Graphics: Large, temporary light boxes used to illuminate brand messaging at trade shows.

- Internal Directional Signage: Backlit wayfinding signs within hospitals, airports, and corporate buildings.

While transparent materials like acrylic may be used where extreme clarity or UV resistance is paramount (such as in exterior glazing), polystyrene frosted sheets remain the go-to standard for interior and short-term exterior light boxes due to their unbeatable combination of superior light diffusion and low material cost.